This Infrastructure Use Case was transferred to the NFDI Section ‘Industry Engagement’.

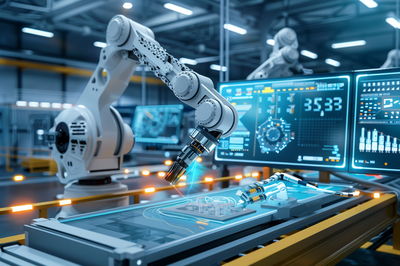

This IUC provides a framework for the integration of materials data into I4.0 manufacturing data infrastructures. This will be implemented as a physical process chain of two polymer systems (sheet molding compounds (SMC), long fiber reinforced thermoplastics (LFT)). The materials data will be integrated in a material database infrastructure. The simulation models are part of a model hierarchy which will be further developed/integrated into a materials model ontology. Based on the model ontology the compatibility of simulation models and material data can be examined and analyzed. Model ontologies are a prerequisite for ontology based knowledge systems and will be made available for the class of long fiber reinforced polymers.

NFDI-MatWerk

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under the National Research Data Infrastructure – NFDI 38/1 – project number 460247524.

NFDI-MatWerk

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under the National Research Data Infrastructure – NFDI 38/1 – project number 460247524.

Subscribe to our newsletter for regular updates about materials science topics!

After subscribing, you will receive an email from us with a confirmation

link.

Only after clicking this link your registration is completed.